7055 Alloy Uns

Posted : admin On 4/9/2022| Chemical Composition Limits | ||||||||||||

| Weight% | Al | Zr | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Other Each | Others Total |

| 7050 min | 87.3 | 0.08 | - | - | 2.0 | - | 1.9 | - | 5.7 | - | - | - |

| 7050 max | 90.3 | 0.15 | 0.12 | 0.15 | 2.6 | 0.10 | 2.6 | 0.04 | 6.7 | 0.06 | 0.05 | 0.15 |

Aluminium alloy 7050 is an aerospace grade of aluminium combining high strength, stress corrosion cracking resistance and toughness. It is particularly suited for heavy plate applications (3' to 6' thick) due to it's lower quench sensitivity and retention of strength in thicker sections. Aluminium 7050 therefore is the premium choice aerospace aluminium for applications such as fuselage frames, bulkheads and wing skins.

Aluminium 7050 plate is available in two tempers. T7651 (AMS 4201) combines the highest strength with good exfoliation corrosion resistance and average SCC resistance. T7451 (AMS 4050) provides better SCC resistance and excellent exfoliation resistance at slightly lower strength levels. Aircraft Materials can also supply 7050 in round bar with temper T74511 (AMS 4342).

Alloys for automotive, vehicle construction, aerospace, engineering, medical ind.etc. Alloy Titanium Grade 03 EN 3.7055 Titanium. AISI UNS BS AFNOR. Alloy 7055-T7751 plate is available in thicknesses from 0.375 in. (9.53mm) to 1.25 in. (31.75mm) in widths up to 110 in. Alloy 7055-T77511 extrusions are available with wall thicknesses from 0.5 in. (12.7mm) to 2.5 in. (63.5mm) with a maximum circle size of 10 in.

Typical Mechanical Properties

| Material | Temper | Thickness | Tensile Strength (ksi) | Yield Strength (ksi) | Elongation in 2' % |

| Alloy 7050 Plate (longitudinal) | T7451 | <2.0 | 74 | 64 | 10 |

| Alloy 7050 Plate (longitudinal) | T7451 | 2.0 -3.0 | 73 | 63 | 9 |

| Alloy 7050 Plate (longitudinal) | T7451 | 3.0 - 4.0 | 72 | 62 | 9 |

| Alloy 7050 Plate (longitudinal) | T7451 | 4.0 - 5.0 | 71 | 61 | 9 |

| Alloy 7050 Plate (longitudinal) | T7651 | 0.25 - 1.0 | 76 | 66 | 9 |

| Alloy 7050 Plate (longitudinal) | T7651 | 1.0 - 1.5 | 77 | 67 | 9 |

| Alloy 7050 Plate (longitudinal) | T7651 | 1.5 - 2.0 | 76 | 66 | 9 |

| Alloy 7050 Plate (longitudinal) | T7651 | 2.0 - 3.0 | 76 | 66 | 8 |

| Material | Temper | Tensile Strength (ksi) | Yield Strength (ksi) | Elongation in 2' % |

| Alloy 7050 Bar (AMS 4340) | T76511 | 79 | 69 | 7 |

| Alloy 7050 Bar (AMS 4340) | T73511 | 70 | 60 | 8 |

| Alloy 7050 Bar (AMS 4342) | T74511 | 73 | 63 | 7 |

Availability

Aluminum Alloy 7050 is available in Plate, Extruded Wire, Wire, Rod and Bar. View Plate stock for all other stock availability of Aluminium Alloy 7050 contact Sales.

Specifications

| Specifications | Extrustions /Part Numbers |

| AMS 4050: 7050-T7451 Plate AMS 4107:7050-T74 Die Forging AMS 4108:7050-T7452 Hand Forgings AMS 4201: 7050-T7651 Plate AMS 4333: 7050-T7452 Forgings AMS 4340: 7050-T76511 Extrusions AMS 4341: 7050-T73511 Extrusions AMS 4342: 7050-T74511 Extrusions | BAC1505-100403-7050-T76511 BAC1506-43-7050T76511 BAC1510-1355-7050T76511 BAC1518-940/7050T76511 BAC1520-1397-7050T76511 |

What's new.......... More News ........ COVID-19 Statement (read full statement here) |

Disclaimer

Every effort is made to ensure that technical specifications are accurate. However, technical specifications included herein should be used as a guideline only. All specifications are subject to change without notice.

7055 Alloy Unsubscribe

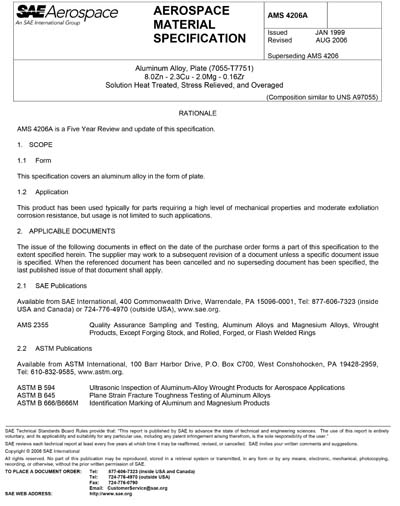

SAE MOBILUS

Subscribers can view annotate, and download all of SAE's content. Learn More »

Aluminum Alloy, Plate 6.4Zn - 2.4Mg - 2.2Cu - 0.12Zr (7150-T7751) Solution Heat Treated, Stress Relieved, and Overaged

AMS4252C

STANDARDAluminum Alloy, Extruded Rod, Bar, and Profiles (7055-T76511) 8.0Zn - 2.3Cu - 2.0Mg - 0.16Zr Solution Heat Treated, Stress-Relieved, and Overaged

AMS4336A

STANDARDAluminum Alloy, Extrusions 6.2Zn - 2.3Cu - 2.2Mg - 0.12Zr (7050-T73511) Solution Heat Treated, Stress Relieved by Stretching, Straightened, and Overaged

7055 Alloy Unsolved Mysteries

AMS4341G

Get Involved

7055 Alloy Unscented

Want to participate in updating this standard?